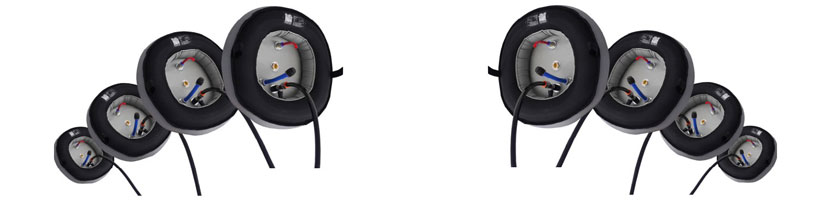

SCHWEISS-SHOP - ARGWELD forming systems forming bladders 6-36, offer a favourable alternative

ARGWELD forming systems Forming bubbles 6-36, offer a favorable alternative, if our conventional tandem systems like PurgElite or QuickPurge cannot be used

© 2026 - schweiss-shop.de