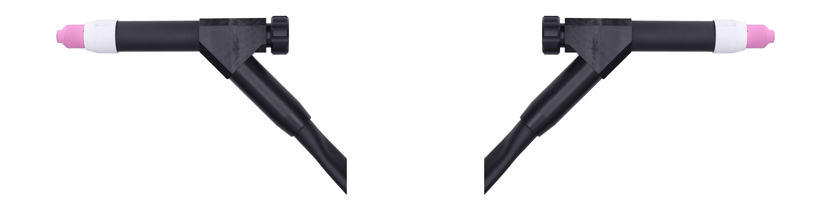

TIG machine welding torches - TTG 220P M and TTW 400P M

The most striking thing about these new machine welding torches is that the hose assembly of the welding torch goes

off to the side at an angle of 45° away from the side. The advantage of this is that if you want to grind or change

the electrode, you can simply electrode can simply be pulled out to the rear. The welding torch remains mounted in

the holder at the preset position. preset position. The idea of changing or grinding the electrode is that it is

pulled out together with the electrode holder. electrode holder is pulled out at the same time. This holder has its

own article number so that a second one can be ordered at the same time. order a second one at the same time. In this

way, you can always prepare a holder with a new, ground electrode and If the electrode comes to a standstill, it can

be replaced very quickly. A spring-loaded thrust piece ensures that this system has a very good current and heat

transfer.

Process

TIG-DC

TIG-AC/DC

Recommended base materials

CrNi steels ferritic / austenitic

Duplex steels

Nickel-based materials

Aluminum materials

Magnesium materials

Copper materials

Recommended fields of application

Plant, container, machine, steel construction

Automotive and supplier industry

Special machinery / construction machinery

Chemical plant construction

Maintenance / repair

Pipeline construction

Rail vehicle construction

Shipbuilding / Offshore